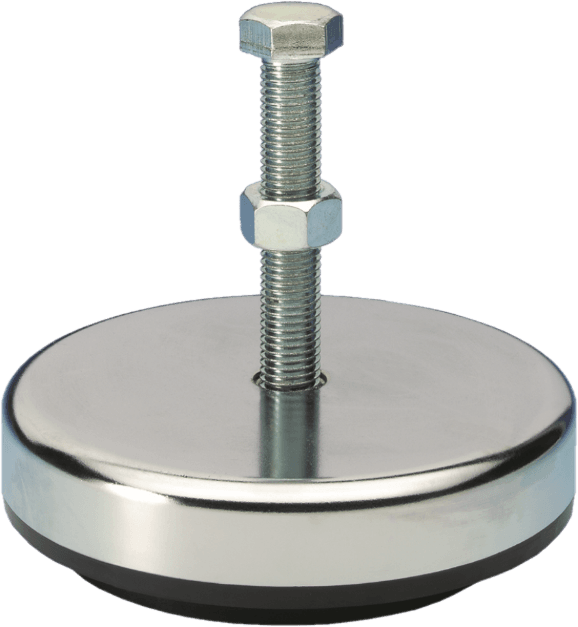

Maschinenfüße

silverflex®GmbH:

Ihr Spezialist für Gummi-Metall-Elemente

Seit über 45 Jahren ist silverflex® Ihr Spezialist für Gummi-Metall-Verbindungen und speziellen Sonderteilen für Schwingungstechnik.

Standorttreu hat das familiengeführte Unternehmen seine Betriebs-und Produktionsstätte seit 1972 in Buchholz/Westerwald. Von hier aus werden im modernen CNC Maschinenpark nach modernsten Fertigungstechniken, Gummi-Metall-Elemente und Gummi-Formteile aller Art in die ganze Welt verschickt. Namhafte Hersteller im Maschinen- und Fahrzeugbau, sowie im Gesundheitswesen zählen zu den Kunden.

silverflex® -Produkte helfen in Aggregaten auftretende Schwingungen zu absorbieren, um somit für einen umweltschonenden und störungsfreien Lauf von Maschinen und Anlagen zu sorgen. Stöße jeder Stärke werden aufgefangen, ob gleich Türen, Tore, Laufkatzen oder anderen beweglichen Teilen. Die Stoßenergie in Endlagen wird so gebremst und schützt Maschinen und Elemente vor Zerstörung und Lärm.

Review Of Apple Pay Payment System For Canadian Online Casinos

Apple Pay is Apple’s mobile payment and digital wallet service, which lets users make in-app and in-person purchases with their Apple devices. Apple Pay can be used with iPhone, iPad, Apple Watch, and Mac. It was first introduced in the US in 2014, and later expanded to Canada, the UK, and other countries. Apple Pay is accepted at many online casinos that cater to Canadian players. Apple Pay is a convenient way to make deposits and withdrawals at these casinos. It is fast, secure, and easy to use. Simply add your credit or debit card to Apple Wallet and you’re ready to go. You can also use Apple Pay with Apple Watch or iPad to make contactless payments. When making a payment, just hold your device near the reader and confirm the payment with Touch ID or Face ID. Apple Pay is a safe and convenient way to play at Canadian online casinos. Try it today!

Apple Pay is a mobile payment system that allows users to make payments online using their Apple devices. The system is designed to be secure and convenient, and it can be used at participating Canadian online casinos. Apple Pay uses Touch ID or Face ID authentication to verify the user’s identity, and the payment is processed through the user’s Apple device using Near Field Communication (NFC) technology. Apple Pay is a secure and convenient way to make online casino deposits, and it can be used at any casino that accepts Apple Pay payments. Click here https://bestcasinosincanada.net/payments/apple-pay to learn more about Apple Pay. Canadian online casinos that accept Apple Pay payments include PartyCasino, Jackpot City, LeoVegas, and Spin Palace. Apple Pay is a great way to make casino deposits, and it’s easy to use. Simply open the Apple Pay app on your Apple device and select the casino you want to deposit at. Then, select the amount you want to deposit and confirm the transaction. Your deposit will be processed instantly, and you’ll be ready to play your favorite casino games. Thanks for choosing Apple Pay! We hope you enjoy using our service.

Sonderteile wie Kupplungen, Dichtungen und Abstreifer werden speziell nach Kundenwunsch entwickelt und produziert. Ein umfangreiches Lager sichert zudem kürzeste Lieferzeiten von Standard- und Normteilen.

Geschäftsleitung in zweiter Generation. Bild v.l.n.r: Sebastian Buda, Leiter Technik und Verkauf – Alexander Buda, GF

Ihr starker Partner für Schwingungstechnik in zweiter Generation

Vom Gummi-Metall-Puffer, über Maschinenfüße bis hin zu Gummi-Metall-Schienen, Sonderringpuffer oder Gummi-Metall-Puffer mit Bodenplatte – bereits in der zweiten Generation der Geschäftsleistung liefert silverflex® zuverlässig Gummi-Metall-Standardteile oder Gummi-Metall-Sonderteile.

Die Produkte zeichnen sich besonders beim Einsatz für Dämpfungen, Federungen oder für elastische Lagerungen aus. Dadurch werden Erschütterungen, Geräusche oder Körperschall verhindert und die fertigen Verbundsysteme finden verschiedenste Einsätze in der Automobilindustrie und in fast allen anderen Industriebereichen. In Maschinen, Apparaten, Messgeräten und Motoren werden die Gummi-Metall-Verbindungen heute verbaut.

Dank spezieller Verfahren, modernem CNC Maschinenpark und einer breiten Auswahl an verschiedenen Gummi-Sorten passen wir Ihnen spezifische Lösungen genau nach Ihren Wünschen an.

Unser Sortiment umfasst folgende Produkte:

- Maschinenfüße

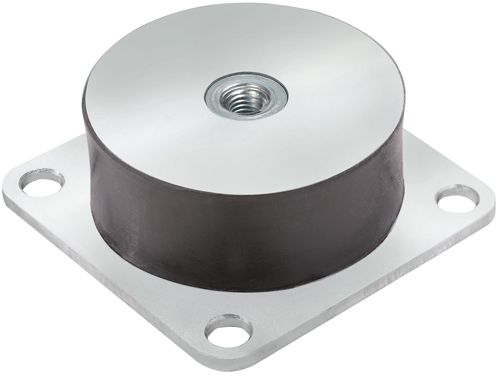

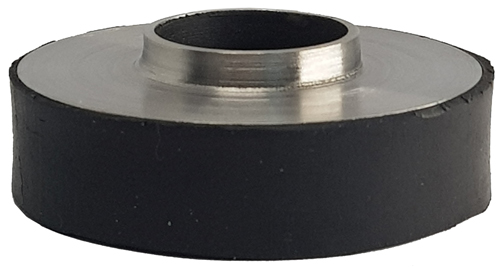

- Gummi-Metall-Puffer

- Standard Edelstahlpuffer

- Gummi-Metall-Puffer mit Bodenplatte

- Silikonpuffer

- Anschlagpuffer

- Hutelemente Niederfrequenzlager

- Sonderringpuffer

- Schwerlastlager

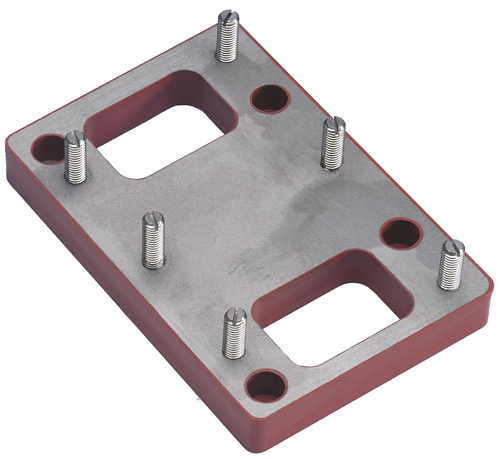

- Gummi-Metall Schienen

- Anschlagschien

- Sonderteile/ Zeichnungsteile

Hierbei zeichnet sich silverflex® nicht nur durch Prozesssicherheit aus, sondern weist enorme Expertise für innovative Prozess-Verfahren auf. Das Ziel ist es, Ihnen stets Produkte höchster Qualität liefern zu können.

Ihre Vorteile bei silverflex® :

Formenbau bei silverflex® : Schnell und präzise

Wir bieten unseren Kunden höchste Flexibilität und maximale Geschwindigkeit.

Qualität, Präzision, Produktionssicherheit und Fertigungsgeschwindigkeit lassen sich nur durch das optimale Zusammenspiel von Produktentwicklung und Werkzeugbau erzielen.

Mittels der intelligenten Verbindung von Gummi-Werkstoffen mit Metall senken Sie das Risiko von Montagefehlern und gewährleisten durch einen festen Stand von Maschinen Betriebssicherheit und Zuverlässigkeit.

silverflex® kann durch den eigenen Werkzeugbau alle Schritte von CAD-Konstruktion bis zum fertigen Werkzeug in-house im Unternehmen durchführen. So können wir Neuanfertigungen, sowie Änderungen von Werkzeugen kurzfristig umsetzen und gleichzeitig Qualität auf höchstem Niveau sicherstellen. Variable Schnittstellen wie DXF, IGES, Step etc. ermöglichen die problemlose Übernahme vorhandener Daten und können sofort in die Fertigung in einem CAM-System integriert werden.

Nachhaltigkeit bei silverflex® : Verantwortung für Mensch und Umwelt

Das Unternehmen silverflex® im Industriepark in Buchholz/Mendt ist mit der Region seit Jahrzehnten verbunden. Standorttreue ist ein wesentlicher Bestandteil der Firmenphilosophie. Hierzu gehört auch die soziale Verantwortung. So kommen knapp die Hälfte der Beschäftigten aus der VG Asbach. Neben den sozialen Aspekten setzt sich silverflex® seit langem auch für den Klima- und Naturschutz ein.

Durch den Einsatz der silverflex® -Produkte werden Umweltbelastungen durch die Absenkung von Lärmemissionen wesentlich reduziert. In den vergangenen zwei Jahren ist auch die Produktion energiesparend mit großen Photovoltaikanlagen umgerüstet worden. Die Anlagen erzeugen mittlerweile umweltfreundliche Energie für über 60 Einfamilienhäuser. Dadurch kann sich silverflex® bilanziell zu einer der wenigen „Nullemissionsbetrieben“ in der Region zählen.